Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

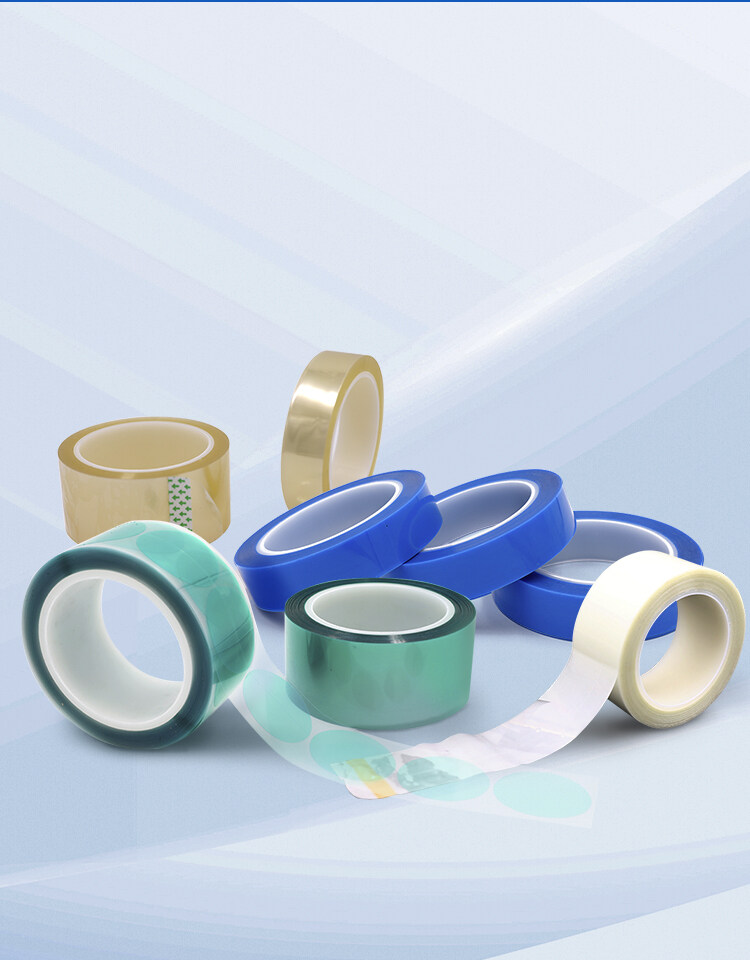

Kapton Tape vs. Blue Tape: A Comprehensive Guide to Choosing the Right Tape for Your Needs

When it comes to choosing the right tape for a project, whether you’re a DIY enthusiast, an engineer, or a crafter, understanding the differences between various types of tape can make a significant difference in the outcome of your work. Two common types of tape that often come up in discussions are Kapton tape and blue tape. While they might seem similar at first glance, each has unique properties that make it suitable for specific applications. In this comprehensive guide, we’ll dive into the details of Kapton tape vs. blue tape, exploring their characteristics, uses, and benefits to help you make an informed decision for your next project.

Understanding Kapton Tape

Kapton tape, also known as polyimide tape, is a high-performance tape made from polyimide film. It’s renowned for its exceptional thermal stability, chemical resistance, and electrical insulation properties. Developed by DuPont, Kapton tape is designed to withstand extreme temperatures and harsh conditions, making it a go-to choice for various high-tech and industrial applications.

Key Features of Kapton Tape:

Thermal Resistance: Kapton tape can handle temperatures ranging from -269°C to 400°C (-452°F to 752°F), making it ideal for environments with extreme heat or cold. This property is particularly useful in electronics and aerospace industries where heat management is crucial.

Chemical Resistance: The tape is resistant to many chemicals, including acids, bases, and solvents. This makes it suitable for use in laboratories and manufacturing environments where exposure to harsh chemicals is common.

Electrical Insulation: Kapton tape provides excellent electrical insulation, making it a preferred choice for use in electrical and electronic applications. It helps prevent short circuits and other electrical issues by insulating sensitive components.

High Adhesion: The adhesive used in Kapton tape ensures that it sticks securely to various surfaces, including metals, plastics, and ceramics. Its strong adhesion is essential for applications where the tape needs to stay in place under challenging conditions.

Applications of Kapton Tape:

Electronics: Kapton tape is widely used in the electronics industry for insulating wires, securing components, and protecting sensitive areas during soldering and manufacturing processes.

Aerospace: In aerospace applications, Kapton tape’s ability to withstand extreme temperatures and its lightweight nature make it an ideal choice for insulating and protecting components in spacecraft and aircraft.

3D Printing: Kapton tape is commonly used on 3D printer beds to ensure proper adhesion of printed objects. Its heat resistance helps maintain a stable printing surface.

Exploring Blue Tape

Blue tape, often referred to as painter’s tape, is a versatile and user-friendly tape primarily used for masking and protecting surfaces during painting or other projects. Unlike Kapton tape, blue tape is known for its ease of use and ability to create clean, crisp paint lines. It’s typically made from a crepe paper backing with a pressure-sensitive adhesive.

Key Features of Blue Tape:

Easy Removal: One of the standout features of blue tape is its ease of removal. It is designed to be removed cleanly without leaving behind residue or damaging surfaces, which is crucial for achieving a professional finish in painting projects.

Surface Protection: Blue tape effectively masks off areas that should not be painted, ensuring that paint only goes where it’s intended. It’s ideal for creating sharp lines and protecting adjacent surfaces.

Adhesion to Various Surfaces: Blue tape adheres well to a variety of surfaces, including walls, wood, glass, and metal. It is designed to stick firmly but can be removed without leaving behind sticky residue.

Versatility: Beyond painting, blue tape has various uses around the home and workshop, including bundling items, labeling, and temporarily holding objects in place.

Applications of Blue Tape:

Painting: Blue tape is most commonly used in painting projects to mask off areas that should not be painted, such as trim, moldings, and adjacent surfaces. It helps achieve clean, straight lines and prevent paint from bleeding into unwanted areas.

Crafting: In crafting, blue tape can be used for creating clean edges, securing materials, and even as a temporary holder for various components.

General Use: Blue tape is handy for many general applications, such as labeling boxes, marking measurements, and temporarily securing items during assembly or repair work.

Kapton Tape vs. Blue Tape: A Comparative Analysis

When comparing Kapton tape vs. blue tape, it’s important to recognize that these two types of tape serve different purposes and excel in different areas. Here’s a side-by-side comparison to highlight their key differences:

1. Material and Composition:

- Kapton Tape: Made from polyimide film with a high-temperature-resistant adhesive.

- Blue Tape: Made from crepe paper with a pressure-sensitive adhesive.

2. Temperature Resistance:

- Kapton Tape: Can withstand extreme temperatures from -269°C to 400°C.

- Blue Tape: Designed for room temperature applications and does not have significant temperature resistance.

3. Chemical Resistance:

- Kapton Tape: Highly resistant to chemicals, acids, bases, and solvents.

- Blue Tape: Not designed for chemical resistance; primarily used for surface protection and masking.

4. Electrical Insulation:

- Kapton Tape: Provides excellent electrical insulation, making it suitable for electronic applications.

- Blue Tape: Does not offer electrical insulation; its primary function is surface masking.

5. Ease of Use and Removal:

- Kapton Tape: Adhesive is designed to stay in place even under extreme conditions, which can make it more challenging to remove.

- Blue Tape: Easily removable without leaving residue, making it user-friendly for masking and painting tasks.

6. Cost:

- Kapton Tape: Generally more expensive due to its specialized properties and manufacturing process.

- Blue Tape: More affordable and widely available, making it a cost-effective option for general masking and painting.

Conclusion

Choosing between Kapton tape and blue tape ultimately depends on your specific needs and the nature of your project. If you’re dealing with high temperatures, harsh chemicals, or require electrical insulation, Kapton tape is the clear choice. On the other hand, if you’re working on a painting project or need a versatile, easy-to-remove tape for general purposes, blue tape is likely the better option.

Understanding the properties and applications of these two types of tape will help you make an informed decision and ensure that you select the right tape for your needs. Whether you’re protecting sensitive electronic components with Kapton tape or achieving clean paint lines with blue tape, each has its place in the toolkit of professionals and DIY enthusiasts alike.