Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

News

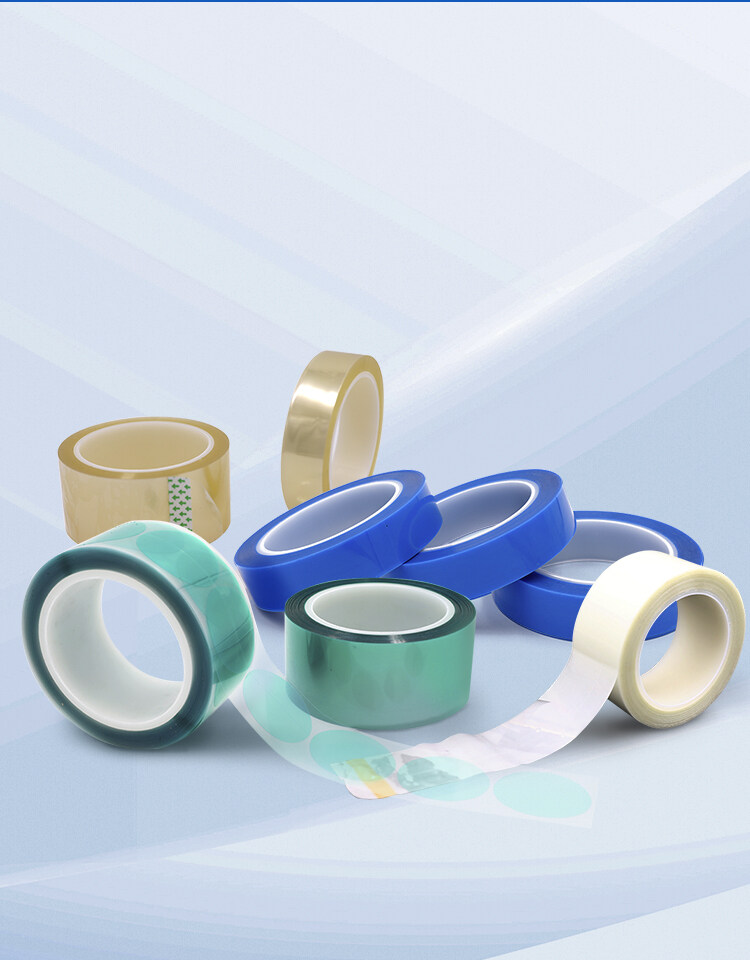

Enhancing Precision with Die Cutting Tape: Revolutionizing Adhesive Tapes for Die Cutting

Die cutting is a widely used method in the manufacturing industry for precision cutting of various materials. One crucial component that aids in achieving impeccable results is adhesive tape for die cutting. In this post, we will explore the significance of die cutting tape, its applications, and how it has revolutionized the die cutting process.

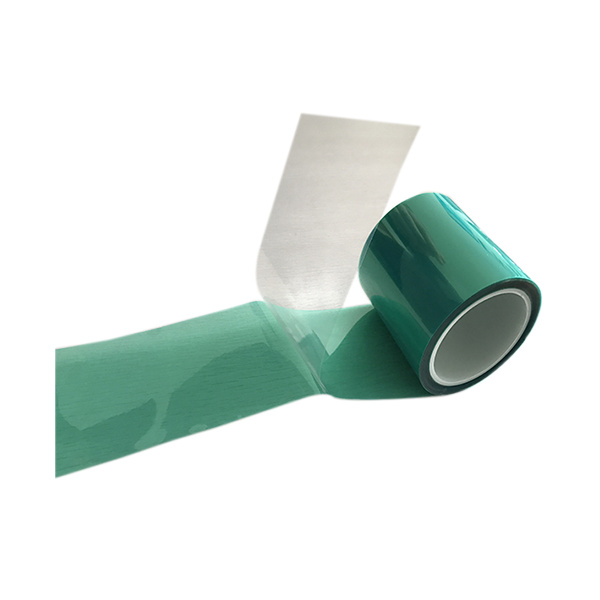

1. Understanding Die Cutting Tape:

Die cutting tape is a specialized adhesive tape designed explicitly for use with die cutting equipment. It possesses unique properties that make it ideal for securing materials during the die cutting process. The tape's primary function is to ensure that the material being cut stays in place and does not shift, resulting in precise and accurate cuts.

2. The Advantages of Die Cutting Tape:

Die cutting tapes offer numerous advantages, making them an indispensable tool in various industries. Firstly, their high adhesive strength provides a secure hold, even on challenging materials. Secondly, die cutting tape eliminates the need for additional clamping or fixing methods, streamlining the die cutting process. Additionally, the tape's conformability enables it to adhere seamlessly to materials, preventing errors caused by material displacement.

3. Applications of Die Cutting Tape:

1). Electronics Industry:

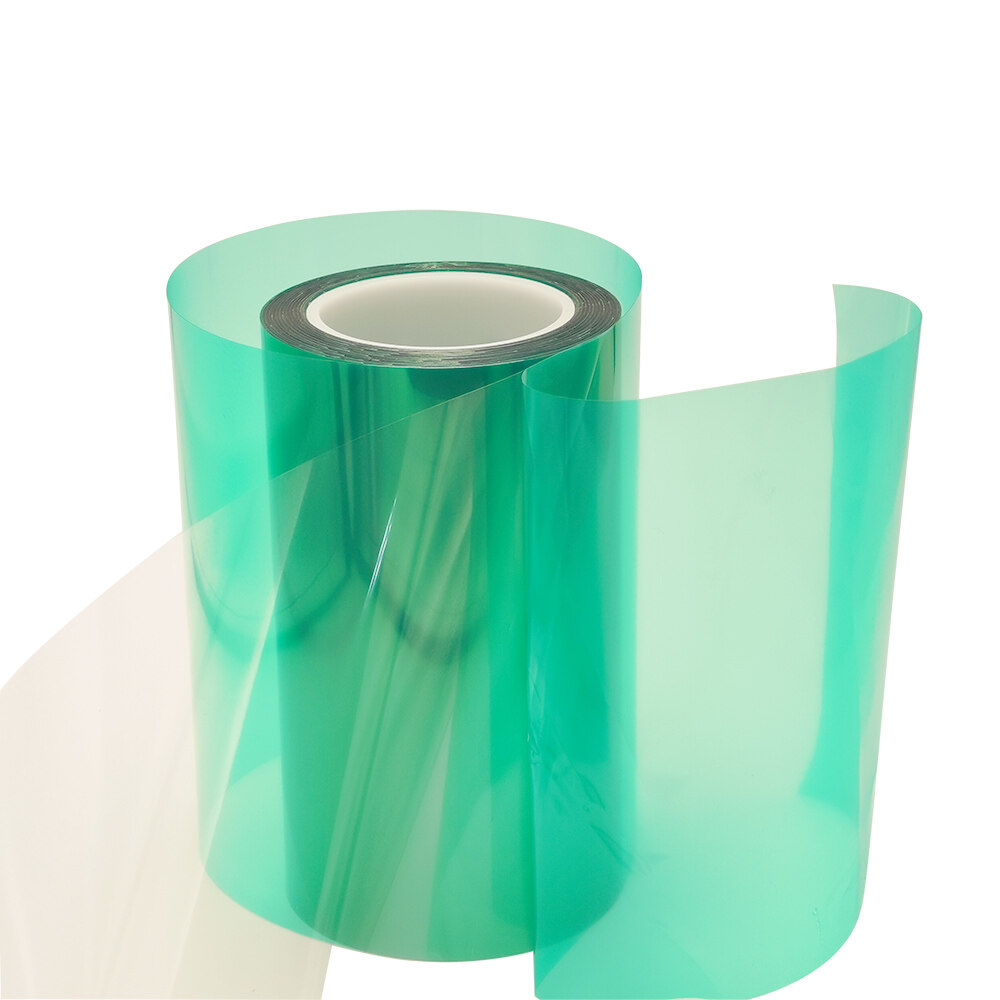

Die cutting tape plays a crucial role in the electronics industry, especially during the manufacturing of printed circuit boards (PCBs) and electronic components. Its ability to hold delicate materials firmly in place ensures precise cuts, reducing production errors and wastage. Die cutting tape also aids in the efficient removal of cut pieces, enhancing productivity.

2). Automotive Industry:

Die cutting tapes find extensive use in the automotive industry, primarily during the production of gaskets, seals, and interior components. These tapes provide a reliable hold on materials such as rubber, foam, and fabrics, allowing for accurate and smooth cuts. Moreover, die cutting tape's excellent dimensional stability ensures consistent results, leading to enhanced product quality.

3). Packaging Industry:

In the packaging industry, die cutting tape enables the efficient and accurate production of die-cut boxes, custom packaging, and labels. Its high-tack adhesive properties securely hold various materials, including cardboard, paper, and films. By eliminating material shifting during the die cutting process, the tape ensures precise cutting and consistent dimensions, optimizing packaging quality.

4. Evolution in Die Cutting Tape Technology:

Over the years, die cutting tape technology has evolved to meet the ever-increasing demands of precision manufacturing. Cutting-edge advancements include the development of tapes with controlled release properties, preventing damage or residue on fragile materials. Additionally, die cutting tapes now come in various widths, thicknesses, and adhesive formulations, catering to diverse application needs.

Die Cutting Tapes Offer High Accuracy in Various Industries

Die cutting tape has revolutionized the die cutting process, providing crucial support for achieving precise and accurate cuts in numerous industries. Its exceptional adhesive properties, conformability, and dimensional stability make it an indispensable tool for manufacturers worldwide. With continuous advancements in die cutting tape technology, we can expect further improvements in precision cutting, reduced wastage, and enhanced productivity across industries.